10 Best Bread in the World to Try in 2024 - breads of the world

Commercial Bakery Ovensecond hand

An ergonomic and effective solution to this is the use of a 3 compartment sink. This tool was made to make the process of cleaning and sanitizing more organized and the risk of cross-contamination is reduced. When it comes to using a three-compartment sink, the key thing is to know the importance of the proper sequence of activities involved and which activity is not allowed in a 3 compartment sink.

You can get all of these features by availing of our digital Food Safety Management System. Our whole program uses artificial intelligence right from building your FSMS up to filling up every monitoring form in your everyday operations. In just 15 minutes, you can get an automatically generated digital FSMS complete with the most necessary documents needed to maintain food safety compliance.

The Food and Drug Administration has provided a set of health guidelines and basic requirements when it comes to using a three-compartment sink under the Food Code of 2017. Accuracy and consistency are invaluable elements when it comes to sanitizing and cleaning. Food handlers cannot neglect any step, or the whole process cycle will be rendered ineffective.

Skipping any of these steps may render the whole cleaning process ineffective and ultimately increase the risk of causing foodborne illnesses. For example, skipping the washing process can leave some food debris on the plates which can sometimes be too hard to remove during rinsing. The sanitation process will not be able to effectively remove this excess food debris and therefore leave the dishes prone to contamination.

Indirect heated oven which operates according to the cyclotherm principle, or heat wheel system. Heating is entirely indirect using central burners outside the baking area, which is then transferred to the product by means of radiator tubes. This oven is very easy to maintain and is fitted with modulating burners with a large adjustable range and guarantees an even heat transfer to the product.

A 3 compartment sink is FDA-recommended, high-efficiency equipment for food establishments without a commercial dishwasher. In addition, not all equipment and utensils are compatible with a commercial dishwasher in terms of their component material and size. A recommended commercial 3 compartment sink must be large enough to accommodate oversized pots and portable machines. Most food safety agencies and health department recommend deep-drawn sinks, rounded corners, stainless steel legs with cross bracing for support, and with enough space in between the previous and following compartments.

Even food trucks must have a dishwashing sink. A 3 compartment sink for the food truck may sometimes be improvised when compared with commercial-scale types. Sometimes, food trucks use a small 3 compartment sink depending on the size of the truck and the needed accommodation of dishes. Alternatively, you may also use a portable 3 compartment sink for convenience.

To remind the responsible food employees for cleaning, our system sends out smart notifications to alert and remind them of the due tasks. Never let a food safety task out of your sight with our digital solution. To make the food safety experience more personal, our system accommodates customizations so you can modify the frequency of cleaning tasks as well as the required sanitizer levels.

Join our list of more than 20,000 customers that are enjoying food safety compliance in the most efficient and effective way possible. Make food safety compliance an easy job for your team and help them boost your services and gain customer confidence.

Learn what cannot be used to dry utensils in a food establishment and how this operation can save you from causing a foodborne illness outbreak.

Commercial Bakery OvenUK

Precision meets efficiency with our robust design for unloading bread and bun pans in a single line with accuracy and consistency at high production rates.

All three compartments of the specified type of sink shall not be used for handwashing or cleaning food, washing towel cloths, or thawing. The sink must be dedicated to the process of cleaning and sanitizing equipment and utensils. If the three-compartment sink was used for any of the mentioned practices, all compartments must be adequately cleaned and sanitized before resuming their intended purpose.

Every food handler must be aware of proper food sanitation practices that must be monitored every day. Learn what are the examples and the best...

With our digital FSMS, you can save a significant amount of time from browsing every monitoring form and filling them out repetitively. Our system can take care of the tedious task and let you focus on what matters the most, ensuring food safety in your operations.

Commercialbreadovenwith steam

To solve this problem, what you need is a digital solution. At FoodDocs, we have built the most efficient solution in a digital platform for your sanitation and cleaning tasks. Our system can automatically create a digital checklist with all of the necessary steps in cleaning the most important sections of your kitchen.

Bestcommercial ovenfor baking cakes UK

If your mechanical dishwasher is able to accommodate all big and small dishes, equipment, and utensils, then there is no need for a 3 compartment sink basin. This is assuming that all of your utensils are dishwasher safe. Otherwise, a food service establishment would significantly benefit from this unit.

Bake off Ovenscommercial

As per the FDA requirement, the water supply for detergent water must be at least 110°F (43°C) or a few degrees higher. The same standard applies to the water used for washing.

Servo-driven walk-in proofer ensures the easiest sanitation and maintenance. Product is directly transferred from Proofer to fully-insulated Griddle.

The principle of a three-compartment sink, do's and don'ts, and how can proper cleaning save your customers - learn all about these topics and more from this article.

In addition to the proper labeling and arrangement of the deep sink compartments, the whole unit must be made out of stainless steel sink which can withstand corrosion from cleaning and sanitizing agents for public health control. The sink must also be easy to disassemble and cleaned in terms of design and texture.

Cleaning and sanitation are two of the main tasks that need to be done on time and correctly to ensure their effectiveness. As such, food handlers must always be alert and oriented with every principle and step related to the two operations. Although a printed checklist can help your team remember every cleaning task, the time you spend browsing which one to do next could have been spent on the actual cleaning and sanitizing processes.

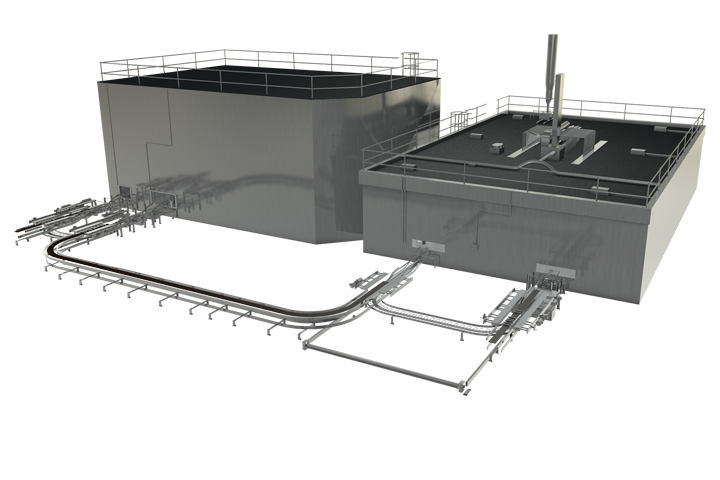

AMF’s BakeTech, Den Boer, and Vesta commercial bakery ovens embody the precision of a master baker combined with the expertise of the industry’s top thermal engineers.

For quick product changeover, Vesta Tray Ovens are ideal for high quality, high-speed baking of bread and buns, particularly those requiring longer bakes time or are higher in density.

With individually programmed temperature zones and controlled air flows, you have more control over your product for the most consistency. AMF’s industrial bread ovens are designed for optimal heat balance throughout the baking process while improving overall energy efficiency.

At AMF, the proof of our success is when our customers rise to the top. AMF is the only complete baking solutions provider with locations throughout North America and the world. We help bakeries minimize their risks and stay online with local service and support around the globe.

Experience the modular brilliance of Den Boer tunnel ovens, designed with independent zone control for unparalleled temperature precision.

Commercial bakery ovenfor sale

AMF’s Den Boer Tunnel Ovens are engineered with modular configurations for the most efficient installations and ability to expand your bakery’s capacity as your production increases.

A robust and high-speed baking solution with high-efficiency Coloraider system increases convection effect on each product at all times.

Before and after using a meat slicer you should always perform pre-and post-operational maintenance to ensure safety. See the step-by-step guide for...

UsedBakery Ovenfor sale UK

Professional bakingovenfor home

Very short baking times, less space require for the oven, efficient and high output. The construction of the baking tunnel and the position of the burners guarantee an even and efficient heat transfer to the product.

Our robust design, tailored for tray ovens, ensures side loading and unloading of bread and bun pans with unmatched accuracy and consistency, even at peak production rates.

Each compartment of the recommended sink must be labeled according to its intended use. Remember that cleaning and sanitizing processes can only become effective if performed in the correct order. The correct order of a three-compartment sink is as follows

A 3 compartment kitchen sink is a piece of manual equipment used for cleaning and sanitizing dishes, utensils, and equipment used in the kitchen. The premise of using the 3 compartment sink systems serves as the basis for more advanced dishwasher cycles. The only difference is, that in a 3 compartment sink, the food handler performs all the cleaning tasks manually. It is a great alternative option for restaurant equipment.

Cleaning and sanitizing equipment and utensils in a commercial kitchen are important food hygiene operations and not random tasks that can be done without any type of organized system. To become effective, they have to be done the correct way all the time. This rule has to be equally applied to all kitchen tools whether big or small.

As recommended by food safety agencies, the 3 compartments of a sink consist of one compartment for washing, rinsing, and sanitizing. The whole setup of a 3 compartment sink was designed to prevent cross-contamination among the utensils and equipment being cleaned. All food establishments must have a dedicated sink used for dishwashing.

Our BakeTech, Den Boer, and Vesta proofers and commercial bakery ovens are crafted with compact designs, offering the utmost flexibility to align with your bakery’s specific footprint and production requirements.

Preparatory and post-operational steps must also be noted before and after using the 3 compartment sink, respectively. Before washing, dishes must be scraped of large food debris to facilitate the next process. After sanitizing, dishes must be properly air-dried before being used for service. The 3 compartment sink faucet must be regularly maintained for proper use.

15920168155

15920168155